Uss Kitty Hawk: Troubleshooting Shipboard Systems For Common Issues

On board the Uss Kitty Hawk, maintaining reliable shipboard systems is essential for safety and readiness. This guide outlines common issues across electrical, propulsion, navigation, and environmental control systems, and offers a practical, high-level approach to troubleshooting that helps crews quickly identify root causes and return to full operation.

Key Points

- Adopt a structured diagnostic process that starts with safety and uncertainty reduction

- Cross-check data from multiple sources to confirm symptom patterns

- Prioritize documentation and change-control to track what was investigated

- Identify typical failure modes such as loose connections, corrosion, and sensor drift

- Schedule preventive maintenance to catch problems before they escalate

Overview of Core Shipboard Systems on Uss Kitty Hawk

Within a carrier’s complex network, the Uss Kitty Hawk relies on diverse subsystems that must interact seamlessly. This section surveys the major domains and explains how they typically present during common issues, without diving into sensitive operational steps.

General Troubleshooting Approach

Approach problems with a calm, methodical mindset. Start with verifying alarms and indicators, collect relevant logs, and confirm whether symptoms are isolated or widespread. Maintain an auditable trail of what was checked and what data was reviewed, then engage qualified technicians or authorities as required. A good approach emphasizes safety, documentation, and using official manuals as the primary reference.

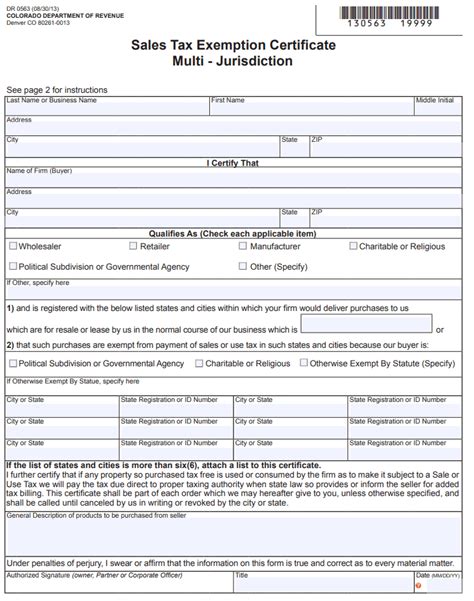

Electrical and Power Systems

Electrical faults are among the most visible and persistent shipboard issues. Common signals include unusual readings, intermittent power loss, or abnormal temperature rises in panels. In most cases, investigators look for loose connections, corrosion, or degraded insulation, and they compare readings against baseline values in the ship’s electrical distribution diagrams. For Uss Kitty Hawk, crews rely on robust redundancy and clear labeling to isolate the affected circuit with minimal disruption to other systems.

Propulsion, Mechanical, and Auxiliary Systems

Propulsion and mechanical subsystems, along with essential auxiliaries, can reveal symptoms such as vibration, unexpected speed changes, or abnormal pressure readings. Troubleshooting focuses on mechanical alignment, lubrication sufficiency, and sensor health. High-level checks include confirming that safeguards and interlocks have not been inadvertently engaged and reviewing recent maintenance entries to spot patterns.

Environmental Control and Sensor Integrity

Environmental control and sensor networks influence crew comfort and data accuracy. Issues often surface as fluctuating temperatures, humidity spikes, or drift in sensor readings. The diagnostic process emphasizes verifying sensor calibration, inspecting environmental enclosures for contamination, and validating controls against expected performance bands documented in official manuals.

Navigation and Communication Systems

Navigation and communications require accuracy and reliability. When anomalies arise—such as discrepancies between displayed data and backups or degraded communication links—the team cross-checks redundant sources, confirms firmware levels, and consults system logs. As with all shipboard diagnostics, the goal is to confirm symptoms before making any configuration changes and to involve qualified personnel when needed.

What are the first steps to take when a power fluctuation is detected on Uss Kitty Hawk?

+

Prioritize safety, acknowledge the alarm, review recent changes, and consult the ship’s power distribution records. Use a high-level diagnostic approach to determine whether the issue is isolated to one circuit or part of a broader electrical subsystem before any isolation or re-energizing actions are considered by authorized personnel.

How does crew verify sensor data when navigation readings seem inconsistent on Uss Kitty Hawk?

+Cross-check multiple independent sources, compare against historical baselines, and review recent maintenance or software updates. Rely on official manuals and redundant indicators to confirm whether the discrepancy is transient or systemic, and document findings.

Why is preventive maintenance important for reducing shipboard failures on Uss Kitty Hawk?

+Preventive maintenance helps catch wear, corrosion, and fatigue before they cause failures in critical subsystems. Regular inspections and schedule-based tasks improve reliability, reduce downtime, and support safe operations across the fleet environment of the Uss Kitty Hawk.

Where can crew find reliable training resources for troubleshooting aboard Uss Kitty Hawk?

+Consult official manuals, onboard training programs, system-specific handbooks, and guidance from safety and engineering officers. Always follow the ship’s approved procedures, and seek supervision when handling unfamiliar or high-risk subsystems.