Common Mistakes In Estimates Of The Cost Of An F22 Raptor

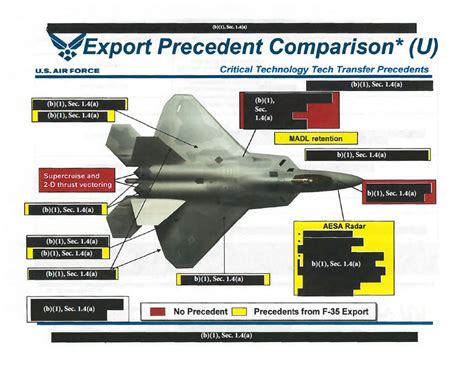

Estimating the Cost Of An F22 Raptor involves more than the sticker price; it includes lifecycle costs, maintenance, readiness, training, and upgrades. In practice, analysts and planners often rely on incomplete data or optimistic assumptions. This article identifies the most common mistakes and offers practical fixes to improve estimation quality.

Key Points

- Focusing on the upfront price while ignoring total cost of ownership, including maintenance, logistics, and long-term support.

- Underestimating maintenance, depot support, and spare parts needed to keep the aircraft mission-ready over its entire life.

- Neglecting inflation, discounting, and financing terms that affect long acquisitions and sustainment budgets.

- Failing to plan for future upgrades, software modernization, and interoperability costs with other systems.

- Blending procurement budgets with operating costs or omitting training, facilities, and contingency allowances.

Understanding the full picture means breaking cost out into procurement, sustainment, and upgrade categories, and applying realistic drivers such as mission readiness, maintenance intervals, and supply chain reliability. When these elements are mishandled, estimates can mislead stakeholders about affordability and risk.

Understanding the components of the Cost Of An F22 Raptor

The Cost Of An F22 Raptor is not a single number; it includes several cost streams such as unit procurement cost, weapons, maintenance, fuel, personnel, facilities, training, and upgrades. Analysts should separate the cost into procurement, sustainment, and upgrade categories, and apply realistic cost drivers such as mission readiness rates and spare parts availability. When analysts fail to separate these, they risk misrepresenting affordability and program risk.

Tip: Use a lifecycle cost framework to capture all expenses over the aircraft's expected service life, often several decades. This helps align planning with actual budgets and strategic priorities.

Strategies to avoid common errors

Adopt standardized cost estimation methods, such as independent cost estimates, reference class forecasting, and explicit risk allowances. Incorporate sensitivity analyses to show how results change with key inputs like maintenance costs, fleet size, and schedule delays, and document all assumptions so decision-makers can review the rationale behind each figure.

What should be included in the Cost Of An F22 Raptor budget?

+

The budget should cover procurement, weapons, maintenance, training, logistics, facilities, personnel, and reserves for potential overruns and technology refreshes across the aircraft’s life cycle.

Why do estimates often diverge from actual costs?

+

Estimates diverge due to incomplete data, optimistic assumptions, and failure to account for long-term maintenance, upgrades, and logistics. Political timelines, supplier risks, and technical challenges can also drive overruns that were not anticipated in early estimates.

How do inflation and financing affect long-term estimates?

+

Inflation and financing terms affect the present value of future payments. If these are not modeled correctly, the long-term cost can appear affordable in nominal terms but become expensive when discounted to present value or when interest rates rise.

How should lifecycle costs be estimated for the F22 program?

+

Lifecycle cost estimation should separate procurement, sustainment, and upgrade costs, include training and facilities, account for depreciation, spares, and support contracts, and include risk allowances for potential delays or technical challenges. Scenario analysis helps illustrate best, expected, and worst cases.

Where can credible cost data for the F22 be sourced?

+

Credible data often comes from official procurement reports, independent cost estimates, industry white papers, and government budgetary documents. Cross-checking multiple sources and transparently documenting assumptions improves reliability.