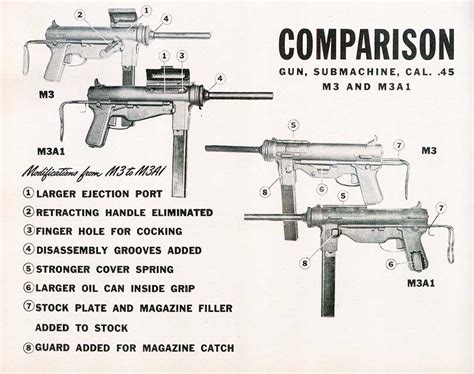

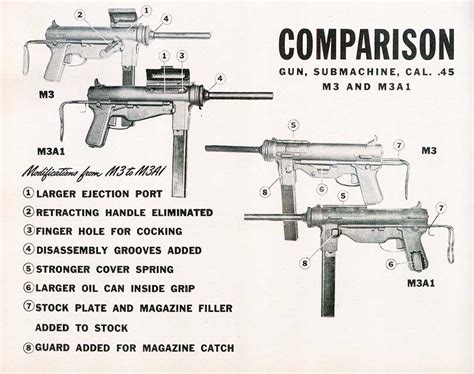

Grease Gun From World War 2 Vs Modern Grease Guns

Grease Gun From World War 2 Vs Modern Grease Guns

The Grease Gun From World War 2 set a baseline for field reliability that still informs tools today. As engines and machinery evolved, lubrication tools expanded beyond simple plunger mechanisms to meet new demands for speed, control, and durability. This article compares the classic Grease Gun From World War 2 with modern grease guns to help you choose the right tool for your workflow.

Key Points

- The Grease Gun From World War 2 emphasized rugged metal construction and straightforward mechanisms designed to resist mud, rain, and rough transport.

- Modern grease guns reduce user fatigue with lighter bodies, ergonomic handles, and balanced weight distribution.

- Power options expanded from manual pumps to pistol-grip, air-powered, and battery-assisted models, increasing workflow speed.

- Improved seals, materials, and cartridge designs extend tool life and keep grease clean under demanding conditions.

- Maintenance has become simpler with fewer moving parts, clear pressure indicators, and easier bleed-and-fill processes.

Historical context: Grease Gun From World War 2

In the World War 2 era, grease guns were built to endure harsh field conditions. They relied on a robust plunger and lever or pistol grip, with simple seals and standard grease cartridges. The focus was on reliability, how long a tool could run without servicing, and how easy it was to repair with basic field kits.

What changed in modern grease guns

Today, grease guns combine durability with user-centric design. Modern models use lighter alloys or reinforced plastics, corrosion-resistant coatings, and better seals. They support multiple loading methods (cartridge and bulk fill), feature adjustable pressure controls to prevent over-greasing, and include quick-connect nozzles and flexible hoses to reach tight spaces. Some models are battery or air-powered for high-volume jobs where speed matters.

Performance, ergonomics and maintenance

Performance now hinges on comfort and control. Ergonomic handles, balanced bodies, and low-recoil pumping reduce fatigue during long shifts. Maintenance focuses on keeping seals clean and replacing worn components before a leak develops. Regular bleed and purge of air pockets ensure consistent lubrication and accurate fill volumes.

Choosing the right tool for your needs

To pick the right tool, consider your typical job scope: small workshop tasks may benefit from a compact pistol-grip manual gun, while heavy equipment maintenance could justify a high-volume, battery-powered or air-powered model. Check cartridge compatibility (cartridge vs bulk fill), nozzle style, maximum operating pressure, and the availability of quick-connect accessories. Also assess durability and warranty against the environments you work in.

How does the Grease Gun From World War 2 compare to modern grease guns in terms of durability?

+

The Grease Gun From World War 2 prioritized rugged metal construction with minimal moving parts, which made it extremely durable in rough field conditions. Modern grease guns retain durability but pair it with lighter materials and corrosion-resistant coatings, improving longevity while reducing fatigue and weight for everyday use.

<div class="faq-item">

<div class="faq-question">

<h3>Can I use modern grease with a historical grease gun?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>In most cases, yes. Modern greases are compatible with older designs, but you should verify viscosity and base type. Using grease that’s significantly thicker than what a WWII-era gun is designed for can increase resistance and wear seals. If in doubt, consult the manufacturer’s guidance or test a small amount first.</p>

</div>

</div>

<div class="faq-item">

<div class="faq-question">

<h3>What should I look for when buying a modern grease gun?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>Key factors include the pumping mechanism (manual lever, pistol grip, or battery/air-powered), cartridge compatibility (cartridge vs bulk fill), maximum operating pressure, nozzle flexibility, weight, and a reliable sealing system. Consider the environments you work in and whether you need speed, reach, or precision.</p>

</div>

</div>

<div class="faq-item">

<div class="faq-question">

<h3>Are WWII-era grease guns still reliable today?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>With proper refurbishment, seals replacement, and clean condition, WWII-era guns can remain functional. However, they generally lack the ergonomic benefits, safety features, and maintenance support of modern designs, so most users upgrade for daily reliability and efficiency.</p>

</div>

</div>

<div class="faq-item">

<div class="faq-question">

<h3>How do maintenance needs differ between old and new grease guns?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>Old guns require periodic lubrication of moving parts, replacement of seals, and checks for rust. New guns emphasize easier bleed routines, better sealing, reduced part counts, and clearer indicators of when a part is worn. Regular cleaning and inspection keep both types performing well, but modern tools typically need less frequent, less intensive maintenance.</p>

</div>

</div>

</div>