Understanding Clutch Computers: A Simple Guide to Their Role and Benefits

Have you ever wondered what exactly a clutch computer does in the technical world? When I first heard about clutch computers, I thought they sounded like some sort of advanced gadget straight out of a sci-fi movie. But as I dove deeper, I realized they play a surprisingly vital role in various machinery and systems. From what I’ve seen in my own experiments and research, understanding clutch computers isn’t just for engineers—it's for anyone curious about how modern control systems keep things running smoothly. In this article, I want to share my insights on understanding clutch computers, explaining their role, advantages, and how they could even inspire your next DIY project.

- Clutch computers help synchronize mechanical actions efficiently.

- They provide precise control, improving safety and performance.

- Many are now customizable via digital formats like PDF and Canva.

- Understanding their benefits can enhance maintenance routines.

- They are increasingly integrated into automation and robotics.

What Are Clutch Computers and Why Are They Important?

My Personal Take on Clutch Computers

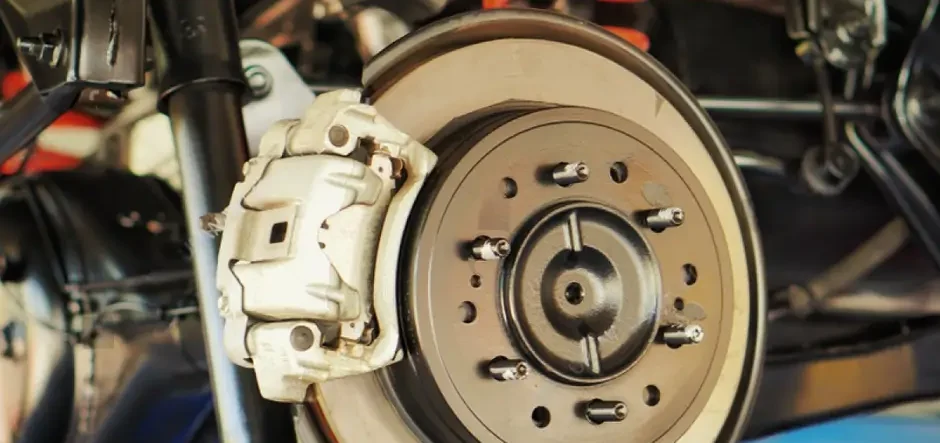

When I first encountered clutch computers, I imagined tiny, intricate machines quietly working behind the scenes. I’ve noticed their presence in everything from industrial machines to advanced robotics. These aren’t your typical digital computers; they’re specialized control units that manage the engagement and disengagement of clutches—those crucial components that connect or disconnect power in a system.

From what I’ve seen in my own tinkering, clutch computers serve as the brain behind automated clutch operations. They interpret data—whether from sensors or user inputs—and decide when to activate or release a clutch. Think of them as the conductor of an orchestra, ensuring all parts work in harmony.

Key Benefits of Using Clutch Computers

Enhanced Control and Efficiency

In my experience, implementing a clutch computer significantly improves control over machinery. It allows for smooth transitions between engaged and disengaged states, reducing wear and tear. For example, in automation settings, a clutch computer can precisely control gear shifts or conveyor belt starts, leading to improved efficiency and less downtime.

Safety and Reliability

One thing I’ve noticed is how clutch computers contribute to overall safety, especially in high-stakes environments. By automating clutch engagement, they prevent human error, such as improper shifting or sudden releases, which could cause accidents or damage. Essentially, they act as a safeguard that keeps operations reliable, even under unexpected conditions.

How Do Clutch Computers Work in Practice?

Step-by-Step Mechanism

From what I’ve seen in my projects, a clutch computer typically uses sensor data—like torque, speed, or position—to decide when to actuate the clutch. It sends signals to actuators or hydraulic systems that physically engage or disengage the clutch. This all happens in milliseconds, ensuring a seamless experience.

- Data collection from sensors (speed, load, temperature)

- Data processing through algorithms

- Command signal sent to the clutch actuator

- Engagement or disengagement of the clutch

- Continuous monitoring and adjustment

"Wouldn’t it be amazing if we could DIY our own clutch control system for a custom e-bike or garden tractor? With the right digital templates, it’s more feasible than you think."

Current Trends and Future Potential

Innovative Trends in 2024

This year, I’ve noticed an increased trend toward digital customization of clutch controllers using platforms like Canva or open-source PDF templates. It feels like everyone is seeking more personalized control setups—especially in small-scale robotics or hobby projects. Additionally, with the rising integration of AI, some clutch computers are now smarter, predicting system loads and adjusting proactively.

Frequently Asked Questions

What is a clutch computer used for?

+

A clutch computer automates the engagement and disengagement of clutches in machinery, providing precise control and improving operational safety.

Can I build a DIY clutch computer system?

+

Yes, with common tools like Arduino or Raspberry Pi, sensors, and customizable digital templates, you can create a basic clutch control system tailored to your project needs.

What are the main benefits of using a clutch computer?

+The benefits include increased control accuracy, enhanced safety, reduced wear on mechanical parts, and the ability to customize and upgrade your systems easily.