F22 Fighter Jet Cost: Key Drivers And Lifecycle Price

The F22 Fighter Jet Cost involves more than the sticker price of a single aircraft. In this article we unpack the main components that drive the F22 Fighter Jet Cost, from initial procurement to long-term lifecycle expenditures. Understanding these elements helps readers evaluate value, risk, and budget planning for advanced air power.

Overview Of The F22 Fighter Jet Cost

The overall price tag is shaped by a mix of upfront flyaway costs, ongoing maintenance, and upgrades that extend the life of the fleet. F22 Fighter Jet Cost is influenced by design choices, production scale, and long-term support commitments. This section highlights how buyers typically model the price pathway from purchase to retirement, with emphasis on how each cost driver interacts with readiness and capability goals.

Key Points

- Unit flyaway price is driven by stealth materials, radar-absorbent design, and integrated sensor suites, which can push the upfront cost above conventional fighters.

- Lifecycle sustainment includes maintenance, depot work, and a resilient supply chain to minimize downtime and keep aircraft mission-ready.

- Engine selection and reliability influence both procurement and long-term operating expenses, including spares and field service needs.

- Modernization and software upgrades during service life add to the total F22 Fighter Jet Cost but can extend capability and interoperability.

- Policy, export controls, and production scale affect unit price and upgrade options, shaping the long-run price trajectory.

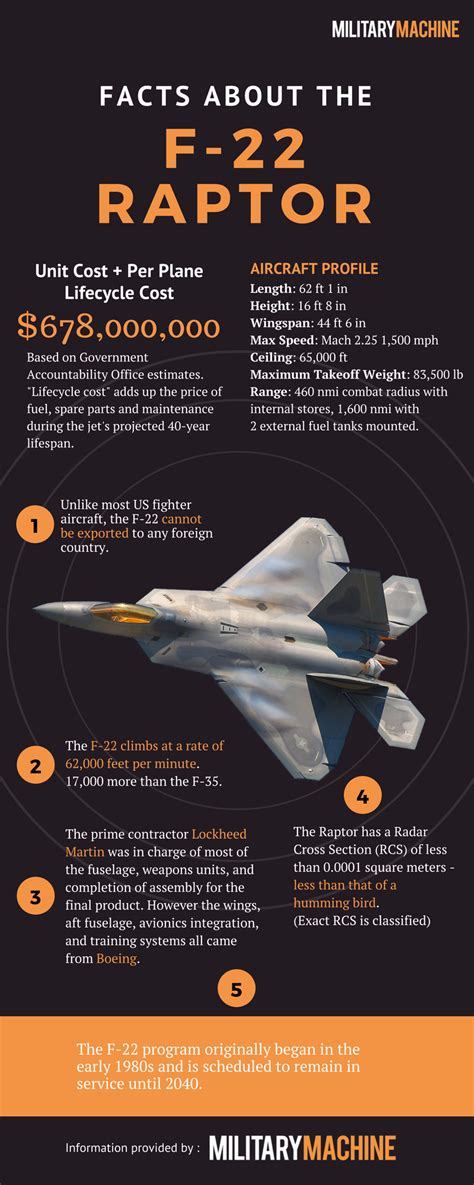

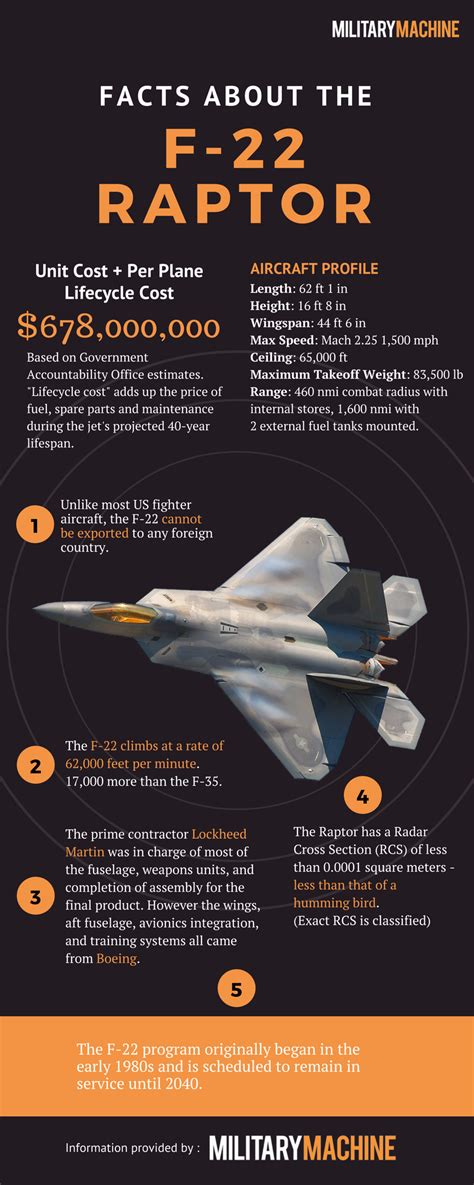

Unit Procurement Price

The procurement phase is a major component of the F22 Fighter Jet Cost, encompassing airframe engineering, stealth features, and the integration of advanced avionics. While historical figures vary, the flyaway price is typically described in the hundreds of millions per aircraft, with adjustments for contracts, inflation, and inflationary budgeting realities. Buyers weigh the price against the expected life of the platform and the level of onboard capability required for mission profiles.

Engine And Propulsion Costs

Powerplant costs and reliability play a central role in the F22 Fighter Jet Cost. High-performance engines, maintenance downtime, and possible engine modules for rapid field repair contribute to both initial price and ongoing expenses. The propulsion system also impacts fuel efficiency, acceleration, and mission readiness, all of which influence the total lifecycle price.

Sensors, Stealth, And Avionics

Advanced sensors, radar, electronic warfare gear, and signature management technologies drive the upfront cost and ongoing upgrade needs. Stealth-related materials and the need for regular software updates mean the F22 Fighter Jet Cost evolves over time as new capabilities are added and vulnerabilities are addressed.

Sustainment, Maintenance, And Readiness

Maintenance routines, depot-level repairs, and a robust supply chain determine how much the fleet costs to keep ready. A well-planned sustainment strategy lowers downtime and reduces the long-term price per flight hour, even if the annual maintenance budget looks high at first glance.

Upgrades And Modernization

Periodic modernization efforts—replacing software, upgrading sensors, or enhancing structural elements—alter the long-term F22 Fighter Jet Cost. Decision-makers balance the benefits of new capabilities with the immediate budget impact and potential downtime during upgrades.

Economies Of Scale, Policy, And Export Controls

Production volume, supplier competition, and policy constraints influence both the initial unit price and the value of future upgrades. Export controls can also limit market access, shaping overall lifecycle cost by affecting availability and lifecycle planning certainty.

What factors most influence the F22 Fighter Jet Cost?

+The main cost drivers include the unit flyaway price for stealth and avionics, ongoing maintenance and depot repairs, propulsion reliability, and the cadence of upgrades. Policy and procurement terms also affect the total price over the aircraft’s life cycle.

How does lifecycle maintenance impact the total F22 Fighter Jet Cost?

+Lifecycle maintenance adds costs through scheduled servicing, depot downtime, spare parts, and logistics. A robust maintenance strategy can reduce unplanned downtime and lower the long-term price per flight hour, balancing upfront expenditure with readiness benefits.

Do upgrades and modernization significantly change the lifecycle price?

+Yes. Upgrades can extend service life and improve capabilities, but they also add upfront and ongoing costs. Strategic modernization schedules aim to maximize capability while controlling the cumulative F22 Fighter Jet Cost over time.

Why is the F22 Fighter Jet Cost often higher than some other fighters?

+Higher costs can reflect advanced stealth coatings, integrated high-end avionics, and sophisticated sensor suites. Additionally, the program’s development history, production scale, and long-term sustainment requirements contribute to a higher total price relative to some non-stealth platforms.

How do export controls affect the F22 Fighter Jet Cost for potential buyers?

+Export controls can limit which countries can purchase or upgrade the aircraft, affecting volume, competition among contractors, and availability of certain options. These factors influence the per-aircraft cost and long-term budgeting for international customers.